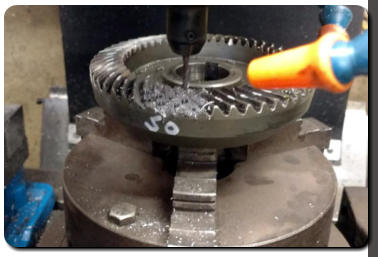

The benefits of re-sharpening the L-

shaped knife can amount to tremendous

savings for the dry pet food and other extrusion process industries.

Please contact us for rates and/or other info.

•

MILLING

•

BROACHING

•

CUTTING

•

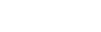

TURNING

•

PUNCHING

•

STEEL ROLLING

•

HYDRAULIC PRESS

•

BORING, SHEARING

•

SHARPENING

•

DRILLING

•

WELDING

•

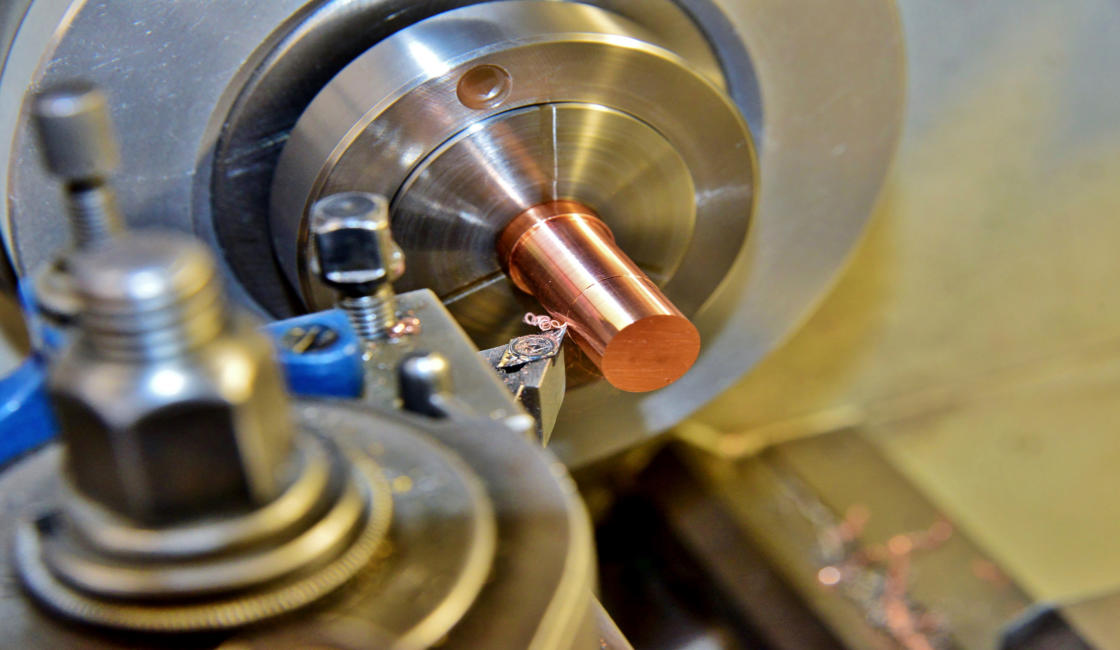

CNC MILLING CENTER

•

CNC LATHE

•

CNC PLASMA TABLE

•

AND MORE

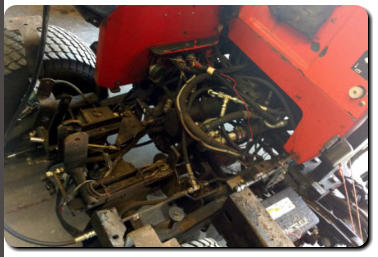

GENERAL MECHANICAL AND

HYDRAULIC MAINTENANCE

Gearboxes, Hose Assembly

Other Hydraulic Equipment

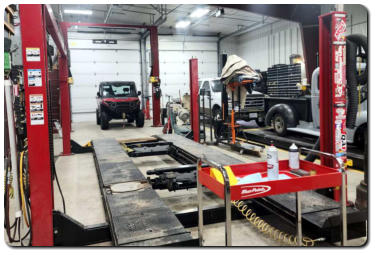

TRUCK, TRAILER, OTHER

EQUIPMENT REPAIR

Brakes, D.O.T.s, Full Service Oil, Lube,

and Filter Change

KNIVES/BLADES AND DIES

Sharpening for the Pet Food Industry

Perham Machine & Repair, Inc

is a family operated full service

machine, fabrication, and

repair shop in Perham, MN.

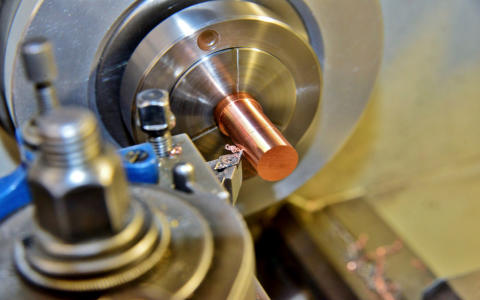

We are equipped with an array of

fabrication equipment, including--

but not limited to-- a CNC mill, lathe,

plasma cutting table, as well as other

lathes, drill presses, bandsaws, a shear,

pinch roller, sandblasting cabinet and

more.

In-house CAD/CAM design.

PMR Inc. sharpens knives and dies for the pet food industry and we service

and repair agricultural, construction, industrial, and other heavy equipment

(skid steers, trailers, tractors, elevators, conveyors…). We perform certified

D.O.T inspections, offer welding services as well as crane service.

We fabricate and repair a variety of parts, agricultural/industrial components

and can do custom design for fire rings, wall decor and other plasma-cut art.

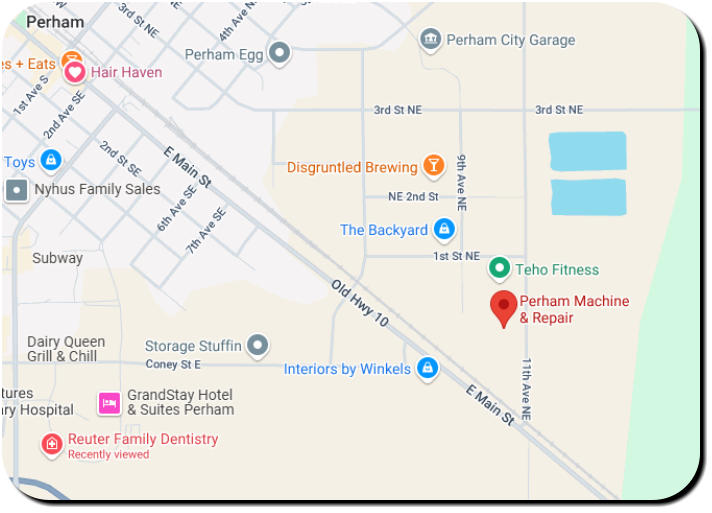

CONTACT PMR INC.

Ph: (218) 346-5222 | Fax: (218) 346-5294

Location:

79 11th Ave. NE

Perham, MN 56573

Robert Marotz:

CAM & CAD / Service / Repair / Fabrication / Sales

Matthew Marotz:

D.O.T.s / Service / Repair / Machine Shop

Manda Marotz:

Graphic Design / Tech & Web / Bookkeeping / Other

Hidee Marotz:

Accounts / Courier / Social Media Manager

PMR Inc. has developed (patent pending) an L-shape heavy duty knife

holder. It holds a replaceable heavy duty knife which can be re-

sharpened up to 10 times or more, depending on the application.

This holder is designed to be used on the same hub style knife holder

used in the pet food, and other extrusion process, industries.

We currently resharpen the standard version of the L-shape knife and

have for 10 years. In that time we have developed a grinding system

with fixtures that allow for sharpening multiple knives at a time-- up

to six times dependent on materials and extrusion proceess. We also

resurface the extrusion dies/inserts which eliminates debris from

knife/die wear, leaving them in pristine shape.

© 2025 Perham Machine & Repair, Inc. | BEE DESIGN

•

MILLING

•

BROACHING

•

CUTTING / KEYWAYS

•

TURNING

•

PUNCHING

•

STEEL ROLLING

•

HYDRAULIC PRESS

•

BORING, SHEARING

•

SHARPENING

•

DRILLING

•

WELDING

•

CNC MILLING CENTER

•

CNC LATHE

•

CNC PLASMA TABLE

•

AND MORE!

Ph: (218) 346-5222 | Fax: (218) 346-5294

Location:

79 11th Ave. NE

Perham, MN 56573

Robert Marotz:

CAM & CAD / Service / Repair / Fabrication / Sales

Matthew Marotz:

D.O.T.s / Service / Repair / Machine Shop

Manda Marotz:

Graphic Design / Tech & Web / Bookkeeping / Other

Hidee Marotz:

Accounts / Courier / Social Media Manager

GENERAL MECHANICAL AND

HYDRAULIC MAINTENANCE

Gearboxes, Hose Assembly,

Other Hydraulic Equipment

TRUCK, TRAILER, OTHER

EQUIPMENT REPAIR

Brakes, D.O.T.s, Full Service

Oil, Lube, and Filter Change

KNIVES AND DIES

Sharpening for the Pet

Food Industry

Perham Machine &

Repair, Inc. is a family

operated full service

machine, fabrication,

and repair shop in

Perham, MN.

We are equipped with

and array of fabrication

equipment, including--

but not limited to-- CNC

mills, lathes, 5x10

plasma cutter, as well

as other lathes, drill

presses, bandsaws,

shears, pinch rollers,

sandblasting cabinet,

brake presses & more.

In-house CAD/CAM

design.

PMR Inc. sharpens

knives and dies for the

pet food industry and

we service and repair

agricultural,

construction, industrial,

and other heavy

equipment (skid steers,

trailers, tractors,

elevators, conveyors,

etc.). We perform certified

D.O.T. instpections, offer welding services as well as

crane service.